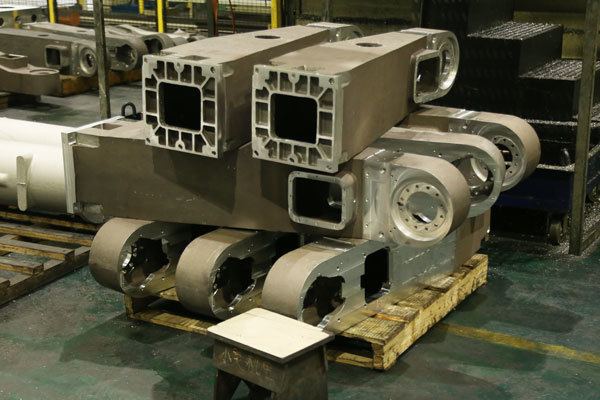

Equipment quality precision machining equipment

Classification:

Tag: aluminum alloy parts processing, aluminum alloy thin-walled parts processing, jiangsu precision machining, jiangsu pressure vessel casting processing

Quality Precision Machining Equipment

Quality precision machining equipment is the backbone of modern manufacturing. It represents the pinnacle of technological innovation and engineering excellence.

These machines are designed to achieve extremely high levels of accuracy and precision. They use advanced mechanisms and control systems to shape and fabricate components with micrometer-level tolerances. The cutting tools and spindles are engineered to provide smooth and precise movements, ensuring that every cut and operation is carried out with utmost accuracy.

The materials used in the construction of these machines are of the highest quality. Sturdy alloys and high-performance metals ensure durability and long service life. The components are precisely machined and assembled to create a reliable and stable platform for precision machining.

In the world of quality precision machining equipment, computer numerical control (CNC) systems play a crucial role. These systems allow for complex geometries and patterns to be programmed and executed with ease. Operators can input detailed designs and instructions, and the machine will carry out the machining process precisely as intended.

The machine tools themselves come in various forms, such as lathes, milling machines, grinders, and drill presses. Each type is specialized for different types of machining operations, but they all share the common goal of achieving exceptional precision.

Quality control is an integral part of the process. High-precision measurement instruments are used to verify the dimensions and tolerances of the machined parts. Any deviations are detected and corrected promptly to maintain the highest quality standards.

The applications of quality precision machining equipment are vast and diverse. They are essential in industries such as aerospace, automotive, medical, and electronics. Components for aircraft engines, precision instruments, and high-tech devices all rely on the accuracy and reliability of these machines.

Maintenance and calibration are critical to ensure the continued performance of the equipment. Regular servicing and fine-tuning keep the machines operating at their peak efficiency and accuracy.

The manufacturers of quality precision machining equipment are constantly striving for improvement. They invest in research and development to introduce new features and capabilities that enhance the machining process. New materials and technologies are explored to push the boundaries of what is possible in precision machining.

Moreover, the operators of these machines require specialized training and skills. They need to understand the complex workings of the equipment and be able to program and operate it effectively to achieve the desired results.

In conclusion, quality precision machining equipment is a vital force in modern manufacturing. It enables the creation of highly accurate and complex components that are essential for the advancement of various industries. With continuous innovation and a focus on quality and precision, these machines will continue to play a crucial role in shaping the future of manufacturing.

Since its establishment, our company has provided world-renowned companies with the machining service of industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, high-voltage power transmission and distribution equipment, large centrifugal air compressor boxes and other precision components. Our company is also one of the few companies in China that are capable of producing and machining medical equipment parts and has long cooperated with the medical equipment companies such as Toshiba and Toray. We have also supplied robot parts for Yaskawa Electric which is one of the four major families of robots in the world, including robot arms and robot bases, with the product accuracy up to 0.02 mm.

Recommended Products

Contact Us

Address: Qiqiao Village, Sian Town, Tongzhou District, Nantong, Jiangsu Province, China.

Telephone: 0086-513-68856085 0086-513-68856090

Fax: 0086-513-68856080

Mobile: 0086-13862902715

E-mail: masahirok@163.com

© 2024 KOIZUMI MACHINERY CO.,LTD. ALL Rights Reserve.