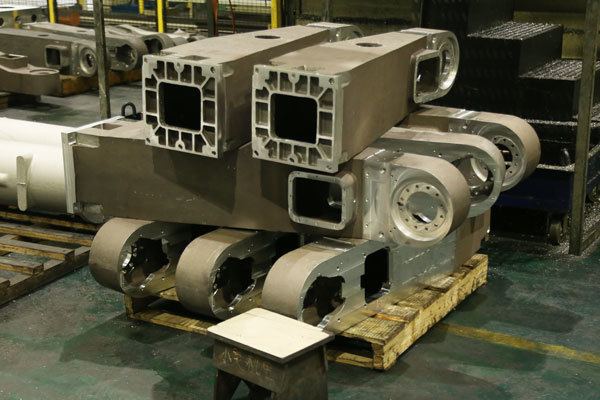

Handling robotic equipment newest industrial robots parts processing

Classification:

Tag: aluminum alloy parts processing, aluminum alloy thin-walled parts processing, jiangsu precision machining, jiangsu pressure vessel casting processing

Founded on July 19, 2007, the company has world-class processing equipment and three-coordinate testing equipment. It is the enterprise with the largest number of CNC machining centers in Nantong, and also has three-coordinate testing equipment with the largest measurement range in East China. Last year, FMS horizontal boring and milling machining center in Niigata, Japan was newly introduced, realizing a new mode of fully automated machining with 2 machine tools sharing 10 worktables. Greatly improve our production capacity and technical level. Since its establishment, the company has been providing industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, and high-voltage power transmission and distribution equipment to world-renowned companies

Newest Industrial Robots Parts Processing: The Future of Manufacturing

The manufacturing industry is constantly evolving, and with the latest advancements in technology, businesses are seeking innovative solutions to improve their production processes. One such solution is the newest industrial robots parts processing, which offers unparalleled precision, efficiency, and flexibility for modern manufacturing needs.

At its core, the newest industrial robots parts processing involves the use of cutting-edge technology and advanced engineering techniques to design and fabricate custom robotic components. These components are specifically tailored to meet the unique requirements of each application, ensuring optimal performance and reliability in even the most demanding environments.

One of the key benefits of the newest industrial robots parts processing is the ability to enhance productivity and reduce costs. By leveraging specialized robotic components that are engineered for precision and speed, manufacturers can achieve faster cycle times, reduced downtime, and increased overall efficiency. This not only leads to cost savings but also allows businesses to scale their operations without sacrificing product quality or consistency.

Another advantage of utilizing the newest industrial robots parts processing is the improved flexibility it provides. With customized components, manufacturers can easily adapt their robots to changing production demands or incorporate new technologies as they become available. This means that businesses can stay ahead of the competition by continuously innovating their processes and offering new products or services to their customers.

But perhaps the most compelling reason to invest in the newest industrial robots parts processing is the potential for increased safety and reduced risk of injury on the factory floor. By designing components that are ergonomically optimized and equipped with advanced safety features, manufacturers can create a safer working environment for their employees while minimizing the likelihood of accidents and downtime caused by human error.

So how do we achieve these remarkable results? Our process begins with a comprehensive consultation to understand your specific requirements, constraints, and objectives. We then work closely with our engineering team to develop a detailed design plan that takes into account factors such as material properties, force requirements, and environmental conditions. Once the design is finalized, we utilize state-of-the-art manufacturing techniques and quality control measures to bring your vision to life. And finally, we provide ongoing support and maintenance to ensure that your custom components continue to perform at peak levels over time.

In conclusion, the newest industrial robots parts processing offers a powerful way to unlock the full potential of your manufacturing operations. By investing in tailor-made solutions that are designed specifically for your needs, you can achieve unprecedented levels of efficiency, flexibility, and safety while staying ahead of the competition. So why settle for generic components when you can have precisely engineered robotic systems that truly transform your business? Contact us today to learn more about how we can help you revolutionize your manufacturing processes with the newest industrial robots parts processing.

Since its establishment, our company has provided world-renowned companies with the machining service of industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, high-voltage power transmission and distribution equipment, large centrifugal air compressor boxes and other precision components. Our company is also one of the few companies in China that are capable of producing and machining medical equipment parts and has long cooperated with the medical equipment companies such as Toshiba and Toray. We have also supplied robot parts for Yaskawa Electric which is one of the four major families of robots in the world, including robot arms and robot bases, with the product accuracy up to 0.02 mm.

Recommended Products

Contact Us

Address: Qiqiao Village, Sian Town, Tongzhou District, Nantong, Jiangsu Province, China.

Telephone: 0086-513-68856085 0086-513-68856090

Fax: 0086-513-68856080

Mobile: 0086-13862902715

E-mail: masahirok@163.com

© 2024 KOIZUMI MACHINERY CO.,LTD. ALL Rights Reserve.