Equipment medical equipment parts process

Classification:

Tag: aluminum alloy parts processing, aluminum alloy thin-walled parts processing, jiangsu precision machining, jiangsu pressure vessel casting processing

Medical Equipment Parts Process

The process of manufacturing medical equipment parts is a highly specialized and intricate field that demands precision, quality, and strict adherence to regulatory standards.

It begins with in-depth research and development. Teams of engineers and scientists work closely to understand the specific needs and requirements of the medical devices. They explore innovative designs and technologies to create parts that are not only functional but also safe and reliable for use in the healthcare environment.

Material selection is of utmost importance. Only high-quality, biocompatible materials are chosen to ensure that the parts do not cause any adverse reactions or complications when in contact with the human body. These materials might include special alloys, polymers, or ceramics that offer the necessary strength, durability, and inertness.

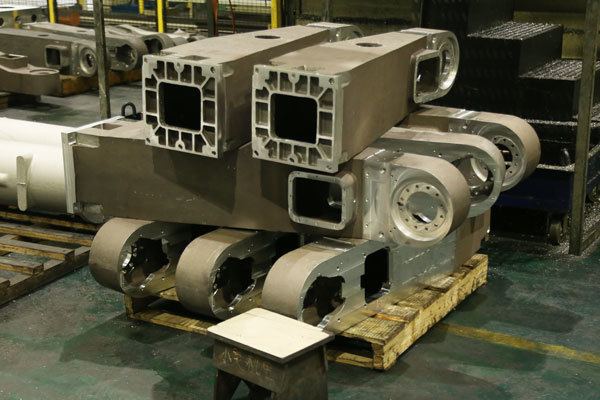

The manufacturing process itself involves a variety of techniques. Precision machining is often utilized to create complex shapes and geometries with exacting tolerances. Advanced manufacturing methods such as 3D printing are also becoming increasingly prevalent, allowing for the creation of customized parts with unique designs.

During the production, strict quality control measures are in place. Multiple inspections and tests are conducted at various stages to ensure that each part meets the highest standards of quality and performance. Non-destructive testing methods like X-rays and ultrasonic inspections are used to detect any hidden flaws or defects.

Surface treatments and coatings may be applied to enhance the functionality of the parts. For example, anti-corrosion coatings can be used to increase the lifespan of the equipment, or special finishes can be added to improve biocompatibility or reduce friction.

Assembly of the medical equipment parts is a meticulous task. Skilled technicians ensure that all components are put together precisely, and all connections are secure and leak-proof. Specialized tools and fixtures are employed to ensure proper alignment and functionality.

In addition to the physical manufacturing, there is a significant focus on regulatory compliance. Medical equipment parts must meet strict regulatory requirements to ensure patient safety. Manufacturers work closely with regulatory authorities to ensure that their processes and products are in line with all applicable laws and regulations.

Furthermore, the industry is constantly evolving to keep up with the latest technological advancements and medical research. This means that the process of manufacturing medical equipment parts is a continuous learning and improvement journey. New materials, techniques, and designs are constantly being explored and incorporated to provide better healthcare solutions.

The result of this meticulous process is a range of high-quality medical equipment parts that play a crucial role in the diagnosis, treatment, and care of patients. From tiny components in surgical instruments to complex assemblies in imaging devices, every part is essential for the effective operation of medical equipment and the delivery of quality healthcare.

In conclusion, the process of manufacturing medical equipment parts is a complex and highly regulated field that requires a combination of scientific knowledge, engineering expertise, and a commitment to quality and patient safety. It is an essential part of the healthcare industry, enabling the development and use of advanced medical technologies that save lives and improve the well-being of patients.

Since its establishment, our company has provided world-renowned companies with the machining service of industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, high-voltage power transmission and distribution equipment, large centrifugal air compressor boxes and other precision components. Our company is also one of the few companies in China that are capable of producing and machining medical equipment parts and has long cooperated with the medical equipment companies such as Toshiba and Toray. We have also supplied robot parts for Yaskawa Electric which is one of the four major families of robots in the world, including robot arms and robot bases, with the product accuracy up to 0.02 mm.

Recommended Products

Contact Us

Address: Qiqiao Village, Sian Town, Tongzhou District, Nantong, Jiangsu Province, China.

Telephone: 0086-513-68856085 0086-513-68856090

Fax: 0086-513-68856080

Mobile: 0086-13862902715

E-mail: masahirok@163.com

© 2024 KOIZUMI MACHINERY CO.,LTD. ALL Rights Reserve.