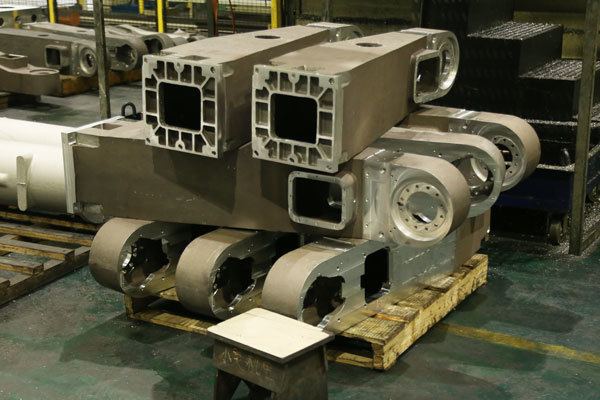

Robotic arm medical surgical robots parts processing

Classification:

Tag: aluminum alloy parts processing, aluminum alloy thin-walled parts processing, jiangsu precision machining, jiangsu pressure vessel casting processing

Aluminum alloy casting

Cast aluminum alloy is an aluminum alloy that fills the mold with molten metal and obtains blanks of various shapes. It has the advantages of low density, high specific strength, good corrosion resistance and casting manufacturability, and is less restricted by the structural design of parts. Divided into Al-Si and Al-Si-Mg-Cu-based medium-strength alloys; Al-Cu-based high-strength alloys; Al-Mg-based corrosion-resistant alloys; Al-Re-based heat-strength alloys. Most require heat treatment to strengthen alloys, eliminate internal stress in castings, and stabilize microstructure and part size. Used in the manufacture of beams, gas turbine blades, pump bodies, pylons, hubs, air intake lips and engine casings, etc. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and supercharger pump parts.

The aluminum alloy used for the required parts is directly obtained by the casting process. It is required to have ideal castability: good fluidity, less shrinkage, hot cracking and cold cracking tendency, less segregation and inhalation. The element content of cast aluminum alloys is generally higher than that of corresponding deformed aluminum alloys, and most alloys are close to eutectic compositions.

Medical surgical robots parts processing is a highly specialized and intricate field that holds significant importance in the medical industry. It involves the meticulous manufacturing and assembling of various components that come together to form these advanced robotic systems.

The parts for medical surgical robots are crafted with extreme precision using advanced technologies and materials. High-quality metals, ceramics, and polymers are selected to ensure durability, biocompatibility, and optimal performance. These materials are then shaped and machined using precise techniques such as laser cutting, milling, and 3D printing.

The processing of these parts requires a deep understanding of the complex mechanics and functions of the surgical robot. Engineers and technicians work closely to design and fabricate components that can accurately perform delicate surgical procedures. Sensors, actuators, and joints are among the critical parts that need to be precisely engineered to enable smooth and controlled movements.

Quality control is of paramount importance in medical surgical robots parts processing. Stringent testing and inspection procedures are in place to ensure that each part meets the highest standards of safety and reliability. Any defects or imperfections can have significant consequences in a surgical setting, so every detail is scrutinized.

The design of the parts also takes into account factors such as miniaturization and ergonomics. The robots need to be compact and maneuverable within the confined spaces of the operating room, while also providing a comfortable and intuitive interface for the surgeons. Advanced software and control systems are integrated to ensure seamless operation and coordination of the robot's actions.

Furthermore, continuous research and development are driving innovation in medical surgical robots parts processing. New materials and manufacturing techniques are being explored to enhance the performance and capabilities of these robots. This leads to improved surgical outcomes, reduced recovery times, and greater precision in medical procedures.

In conclusion, medical surgical robots parts processing is a complex and evolving field that combines cutting-edge technology, engineering expertise, and a commitment to patient safety and care. The precise processing of these parts is essential for the success of surgical robotic systems in revolutionizing modern healthcare. Medical surgical robots parts processing, medical surgical robots parts processing, medical surgical robots parts processing.

Since its establishment, our company has provided world-renowned companies with the machining service of industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, high-voltage power transmission and distribution equipment, large centrifugal air compressor boxes and other precision components. Our company is also one of the few companies in China that are capable of producing and machining medical equipment parts and has long cooperated with the medical equipment companies such as Toshiba and Toray. We have also supplied robot parts for Yaskawa Electric which is one of the four major families of robots in the world, including robot arms and robot bases, with the product accuracy up to 0.02 mm.

Recommended Products

Contact Us

Address: Qiqiao Village, Sian Town, Tongzhou District, Nantong, Jiangsu Province, China.

Telephone: 0086-513-68856085 0086-513-68856090

Fax: 0086-513-68856080

Mobile: 0086-13862902715

E-mail: masahirok@163.com

© 2024 KOIZUMI MACHINERY CO.,LTD. ALL Rights Reserve.