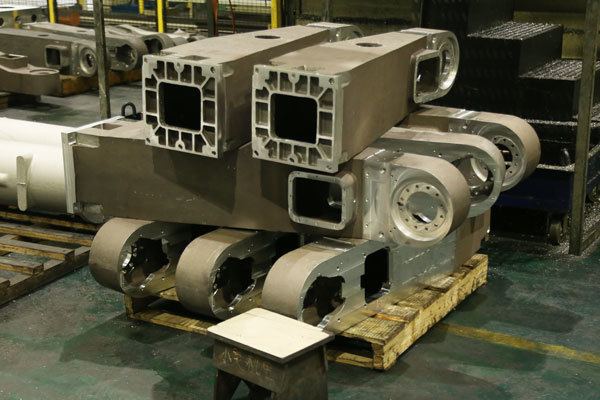

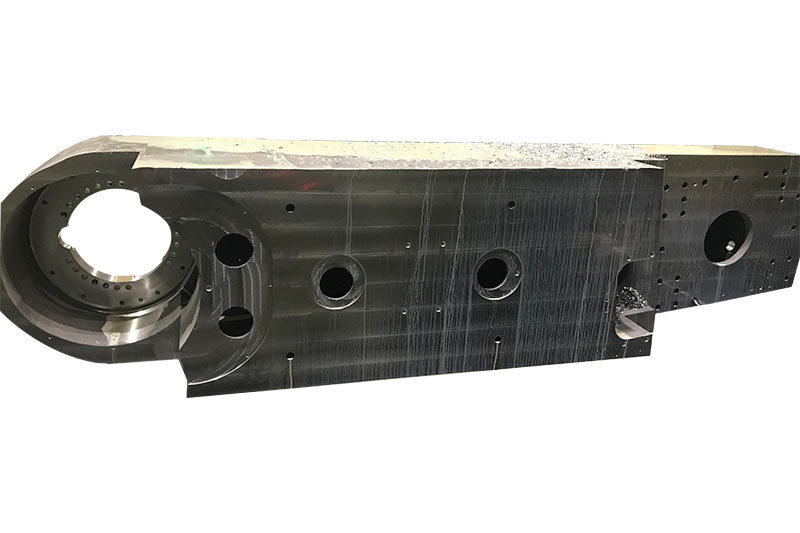

Robotic arm quality industrial robots parts processing

Classification:

Tag: aluminum alloy parts processing, aluminum alloy thin-walled parts processing, jiangsu precision machining, jiangsu pressure vessel casting processing

Aluminum alloy casting Quality industrial robots parts processing is the cornerstone of a successful and efficient industrial robotic system. It involves a meticulous and precise approach to ensure that every component meets the highest standards of quality and performance.

Cast aluminum alloy is an aluminum alloy that fills the mold with molten metal and obtains blanks of various shapes. It has the advantages of low density, high specific strength, good corrosion resistance and casting manufacturability, and is less restricted by the structural design of parts. Divided into Al-Si and Al-Si-Mg-Cu-based medium-strength alloys; Al-Cu-based high-strength alloys; Al-Mg-based corrosion-resistant alloys; Al-Re-based heat-strength alloys. Most require heat treatment to strengthen alloys, eliminate internal stress in castings, and stabilize microstructure and part size. Used in the manufacture of beams, gas turbine blades, pump bodies, pylons, hubs, air intake lips and engine casings, etc. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and supercharger pump parts.

The aluminum alloy used for the required parts is directly obtained by the casting process. It is required to have ideal castability: good fluidity, less shrinkage, hot cracking and cold cracking tendency, less segregation and inhalation. The element content of cast aluminum alloys is generally higher than that of corresponding deformed aluminum alloys, and most alloys are close to eutectic compositions.

Quality industrial robots parts processing is the cornerstone of a successful and efficient industrial robotic system. It involves a meticulous and precise approach to ensure that every component meets the highest standards of quality and performance.

The process starts with the selection of superior materials that possess the necessary strength, durability, and functionality. These materials are carefully sourced and tested to guarantee their suitability for the demanding requirements of industrial robot parts. Skilled engineers and technicians then employ advanced manufacturing techniques to shape and fabricate these materials into the desired parts.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems play a crucial role in quality industrial robots parts processing. They allow for accurate and detailed designs, ensuring that the parts are engineered to exact specifications. Machining processes such as milling, turning, and grinding are carried out with precision to achieve the required tolerances and surface finishes.

During the manufacturing process, strict quality control measures are implemented at every stage. Inspections and tests are conducted to detect any flaws or deviations from the standards. This includes dimensional checks, material analysis, and performance evaluations. Any issues are promptly addressed to maintain the integrity of the parts.

Surface treatments and coatings are often applied to enhance the functionality and lifespan of the parts. These can include anti-corrosion coatings, lubricants, and hardening treatments to improve wear resistance. Assembly of the parts is also a critical step, ensuring that they fit together seamlessly and function in harmony within the robot system.

Attention to detail is paramount in quality industrial robots parts processing. Even the slightest defect or imperfection can have a significant impact on the performance and reliability of the robot. The parts must be able to withstand the rigors of continuous operation, heavy loads, and harsh industrial environments.

Moreover, continuous improvement and innovation are integral to maintaining high-quality standards. New technologies and manufacturing methods are constantly being explored and incorporated to enhance the quality and efficiency of the processing. This ensures that industrial robots remain at the forefront of modern manufacturing.

In conclusion, quality industrial robots parts processing is a complex and demanding discipline that requires a combination of expertise, technology, and a commitment to excellence. By ensuring the highest quality in the processing of parts, industrial robots can perform with precision and reliability, driving productivity and competitiveness in the industrial sector. Quality industrial robots parts processing, quality industrial robots parts processing, quality industrial robots parts processing.

Since its establishment, our company has provided world-renowned companies with the machining service of industrial robots, medical surgical robots, medical CT machines, wind power generation equipment, high-voltage power transmission and distribution equipment, large centrifugal air compressor boxes and other precision components. Our company is also one of the few companies in China that are capable of producing and machining medical equipment parts and has long cooperated with the medical equipment companies such as Toshiba and Toray. We have also supplied robot parts for Yaskawa Electric which is one of the four major families of robots in the world, including robot arms and robot bases, with the product accuracy up to 0.02 mm.

Recommended Products

Contact Us

Address: Qiqiao Village, Sian Town, Tongzhou District, Nantong, Jiangsu Province, China.

Telephone: 0086-513-68856085 0086-513-68856090

Fax: 0086-513-68856080

Mobile: 0086-13862902715

E-mail: masahirok@163.com

© 2024 KOIZUMI MACHINERY CO.,LTD. ALL Rights Reserve.